A new revision of the IPC/WHMA-A-620 standard designated “D” has come into force. It is now available in Polish.

IPC standards are developed by the Association Connecting Electronics Industries and include requirements for the design, assembly and repair of electronics and the assembly of cables and wire harnesses. The standards are used by contracting authorities and contractors worldwide to facilitate communication regarding the expected quality of product performance.

The IPC/WHMA-A-620 standard titled Requirements and Acceptance for Cable/Wire Harness Assemblies – commonly known as the “620s” is one of the most important standards used in modern wire harness manufacturing. It covers, among other things, criteria for cable preparation, soldering and crimping, IDC connections, ultrasonic welding, wire splices, connector assembly, injection/pouring, measurement of cable assemblies and wires, marking/labelling, coaxial and biaxial cable connections, protection and shielding of wire harnesses, final product assembly, and electrical and mechanical testing.

Significant changes that have appeared in the requirements of Revision D of IPC/WHMA-A-620 include:

- Target Condition – criteria for the Target condition have been dropped, which means that now there are criteria for the Acceptable condition, Process Indicator, Defect, combined conditions or undefined conditions,

- Criteria for maximum limits of solder batch impurities have been introduced,

- Requirements for crimp terminations have been expanded to include criteria for the use of heat shrink tubing,

- The guidelines for IDC connections have been updated,

- New criteria have been introduced for injection/molding in flexible feed bands,

- Criteria for final product assembly have been updated and extended,

- Publication of criteria for solderless wrapped connections has been abandoned referring any interested parties to the MIL-STD-1130 standard,

Publication of criteria for solderless wrapped connections has been abandoned referring any interested parties to the MIL-STD-1130 standard,

– IPC/WHMA-A-620 CIS – Requirements and acceptances for the assembly of cables and wire harnesses – on the dates – 17.05.2021-20.05.2021,

– IPC/WHMA-A-620 CIS + practice – Requirements and acceptances for cable and wire harness assembly + practical classes in wire harness making – 17.05.2021-21.05.2021,

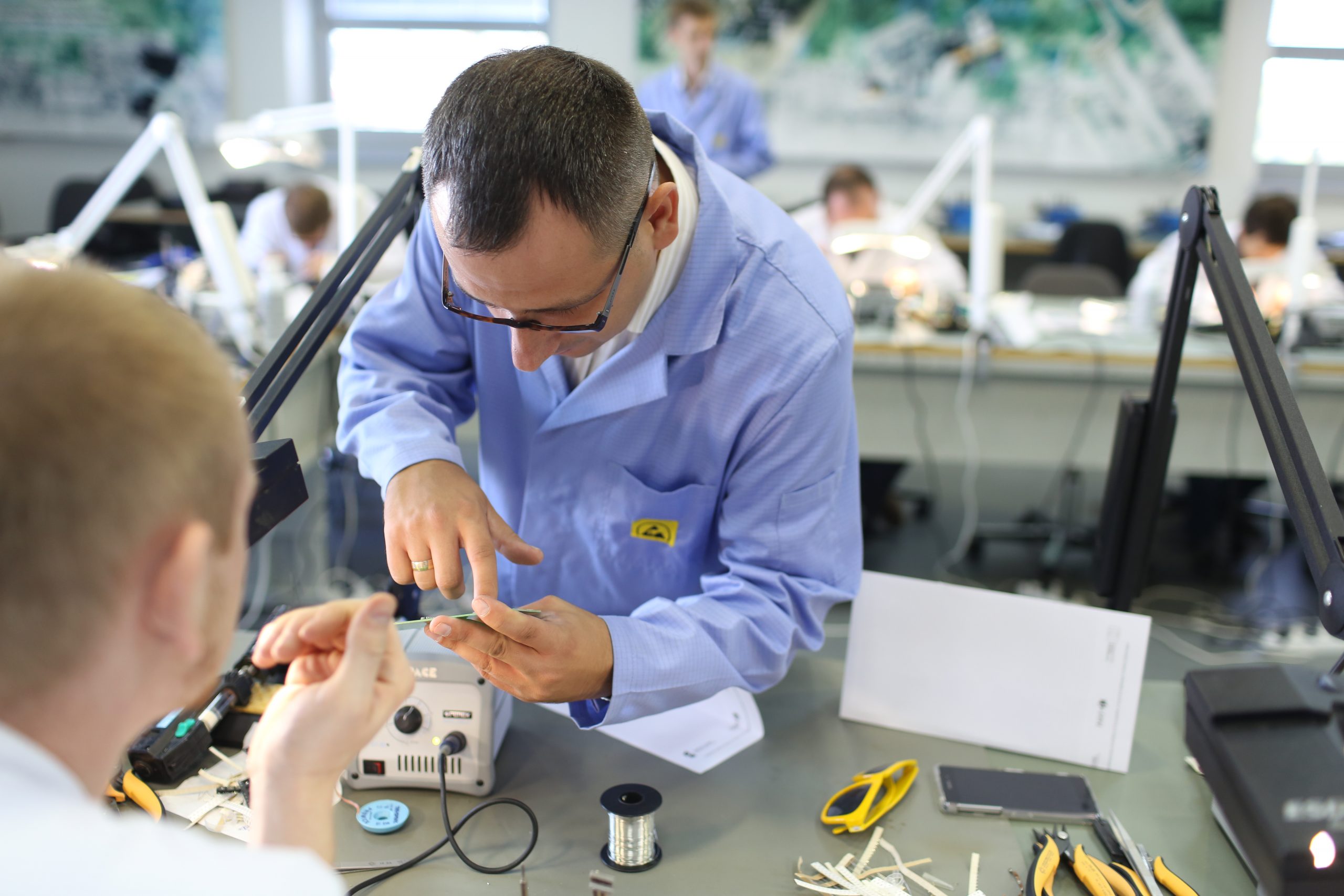

It is worth mentioning that during the practical classes in wire harness creation, participants have the opportunity to work with tools and equipment used, among others, in the military and SPACE industries.

The Polish version of Revision D, which has just been published by the IPC Association, like all its previous versions, has been translated in cooperation with the staff of RENEX ELECTRONICS EDUCATION CENTER – the largest and longest operating IPC AUTHORISED TRAINING CENTER in Central and Eastern Europe. The Center offers training for electronics engineers covering the full range of the IPC standards, as well as courses on anti-static protection. RENEX ELECTRONICS EDUCATION CENTER trainers have almost 20 years of experience in developing IPC standards and training materials, as well as conducting authorised IPC training courses. It is also worth mentioning that the RENEX EEC staff made a significant contribution to the development of a practical module on wire harnessing according to the IPC/WHMA-A-620 guidelines, sitting together with IPC staff on the IPC Technical Committee.

The Polish entity prides itself on having trained more than 30,000 professionals nationally and internationally and, particularly importantly, on being qualified to deliver courses and grant authorisations even at the IPC Certified Trainer level.

Renex Training Centre:

Increasing access to knowledge in electronics manufacturing and repair is one of the pillars of our business. We are glad that the cooperation with the IPC association, which started over 20 years ago, is still developing, and the professionalism and level of expertise of our specialists is appreciated. – The comments were made by Ms Marzena Szczotkowska-Topić and Mr Predrag Topić – co-owners of RENEX Group which includes RENEX Electronics Education Centre.

IPC AUTHORISED TRAINING CENTRE operates within RENEX TECHNOLOGY AND TRAINING CENTRE, a consulting, training and R&D facility created to fulfil RENEX Group’s mission – to support the development of the electronics industry.

Apart from IPC subjects, the center provides courses in programming and operating industrial robots and production equipment, as well as advisory support in developing electronics designs and optimising the operation of production lines.

Renex Technology Centre and Demo Room:

For the use of those interested there are technological facilities available on site, including complete lines for the production and service of electronics, a steel processing park, CNC processing equipment, a powder paint shop, robotic workstations for production optimisation and inspection equipment – X-ray and optical.

RENEX EEC is an authorised distributor of IPC materials. The full contents of Revision D of the IPC/WHMA-A-620 Standard can be ordered at office@ipctraining.pl.

Learn more about IPC AUTHORIZED TRAINING CENTER at www.ipctraining.pl

Find out more about RENEX TECHNOLOGY AND TRAINING CENTER at www.renex.pl/centrum-technologiczne

Find out more about RENEX Group at www.renex.pl