TECHNOSYSTEM has announced an increase in the capacity and efficiency of its SMT production lines due to an investment in a YAMAHA YSM20 pick&place and a second YAMAHA YCP 10 solder paste printer. The entire production process has also been covered by the modern YAMAHA DASHBOARD data collection and traceability systems.

Technosystem from Piaseczno is a manufacturing company operating on the market for over 10 years specializing in the electronics manufacturing service. The company enjoys a high reputation in the market providing services of import and assembly of electronic components. For the recent year it has been operating in a newly built production facility, which enabled the company to significantly develop its machinery park.

RENEX Group, as a representative of YAMAHA SMT, supplied and comprehensively implemented the equipment and systems of the investment: YSM20 automatic pick & place, YCP10 solder paste printer and DASHBOARD software, as well as conducted appropriate training for operators. The Group will also provide warranty and post-warranty service for the delivered equipment during its use.

Our previous assembly capacity of 20 million components per month became insufficient as the company grew. The last year and the good contract prospects despite the crisis confirmed our earlier assumptions about the need to expand our SMT production lines. At the same time we noticed that the increasing amount of data concerning components and produced electronics was already beyond the real possibilities of analysis of our specialists. Looking for a solution to the situation we turned to our long-term partner – RENEX Group. In the course of joint evaluation of the existing situation and development possibilities we have selected solutions in the form of a new pick&place YAMAHA YSM20 and a second solder paste printer YAMAHA YCP10. The purchase has increased the line’s productivity by over 60 thousand components per hour according to IPC 9850 standard – outlines Mr. Wojciech Niedźwiedź, Technosystem President.

The mission of RENEX Group is to provide comprehensive support for the electronics industry and to support its development. Multilevel cooperation with the Technosystem company, within the framework of which we have provided and delivered not only significant devices of the SMT line, but also industrial furniture and equipment of our production, as well as provided advisory, logistic, training and service support, is a perfect example. We believe that the long-term partnership and the highest level of service translate not only into the development of us and our customers but also affect the development of the entire electronics industry. We look forward to further years of fruitful cooperation. – commented Mrs Marzena Szczotkowska-Topić and Mr Predrag Topić – owners of RENEX Group.

YAMAHA YSM 20 pick & place unit is a versatile platform that can be equipped with up to 128 8 mm feeders and quick changeover systems. Replacement of this device allowed for increased flexibility of the entire line while maintaining the same production area.

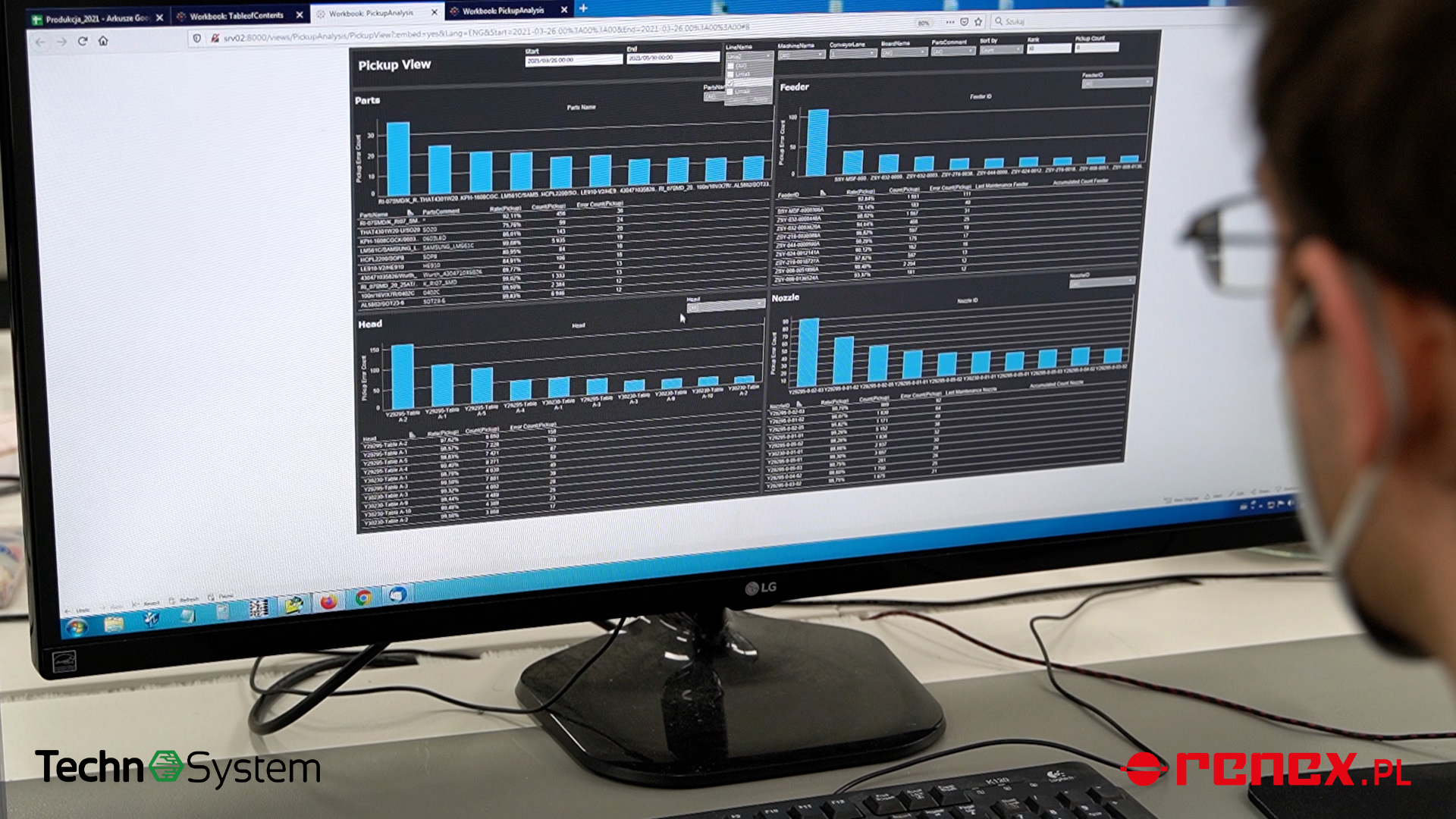

YAMAHA DASHBOARD traceability software introduced for all Technosystem equipment with full job analysis and statistics allows the company to compile data on components, production, and products. For 6 years now, the company has been able to identify each component used in a specific electronic package. For an individual product – an electronic package – a full process history can be created specifying, among other things, when it was assembled, on what machines, what operator was on that line, what components were used, from which supplier they came, on what day of the month and by whom they were received in the warehouse and entered into the system. Thanks to the investment in the new system, the data allows for full analysis of undesirable situations such as downtime and drawing conclusions how to prevent them in the future. YAMAHA DASHBOARD is compatible with the storage system as well as with equipment for storing and counting components such as X-ray counters and cabinets for SMD components. All of this adds up to an overall increase in productivity for your company.

Within the earlier cooperation between the companies, RENEX Group provided Technosystem with equipment for the production facility, including REECO Antistatic Furniture nominated recently to the TERAZ POLSKA Emblem and gaining recognition in foreign markets. The investment included, among others, working stations with electrically adjustable table tops based on REECO Premium Antistatic Tables.

ABOUT RENEX GROUP

The RENEX Group is a company with over 30 years of tradition, specializing in providing comprehensive support in the field of electronics production. This includes extensive technical and commercial consulting, training and service. As part of this mission, the Group has developed RENEX TECHNOLOGY AND TRAINING CENTER, where partners and customers can select solutions, equipment and technologies appropriate to their needs with the help of RENEX experts and using complete production lines and DEMO ROOMs available on site. In addition to consulting support, the Group also specializes in provideing training. It includes the largest AUTHORIZED IPC TRAINING CENTER in Central and Eastern Europe, which provides training in IPC standards and ESD protection. In addition, RENEX Group provides customized training in the proper operation and programming of production equipment and industrial robots as part of YAMAHA AUTHORIZED TRAINING CENTER. Our mission of providing comprehensive support is completed by a full range of maintenance and after-sales services, the level of which has recently been confirmed by the award granted by YAMAHA for the Best SMT Service in Europe.