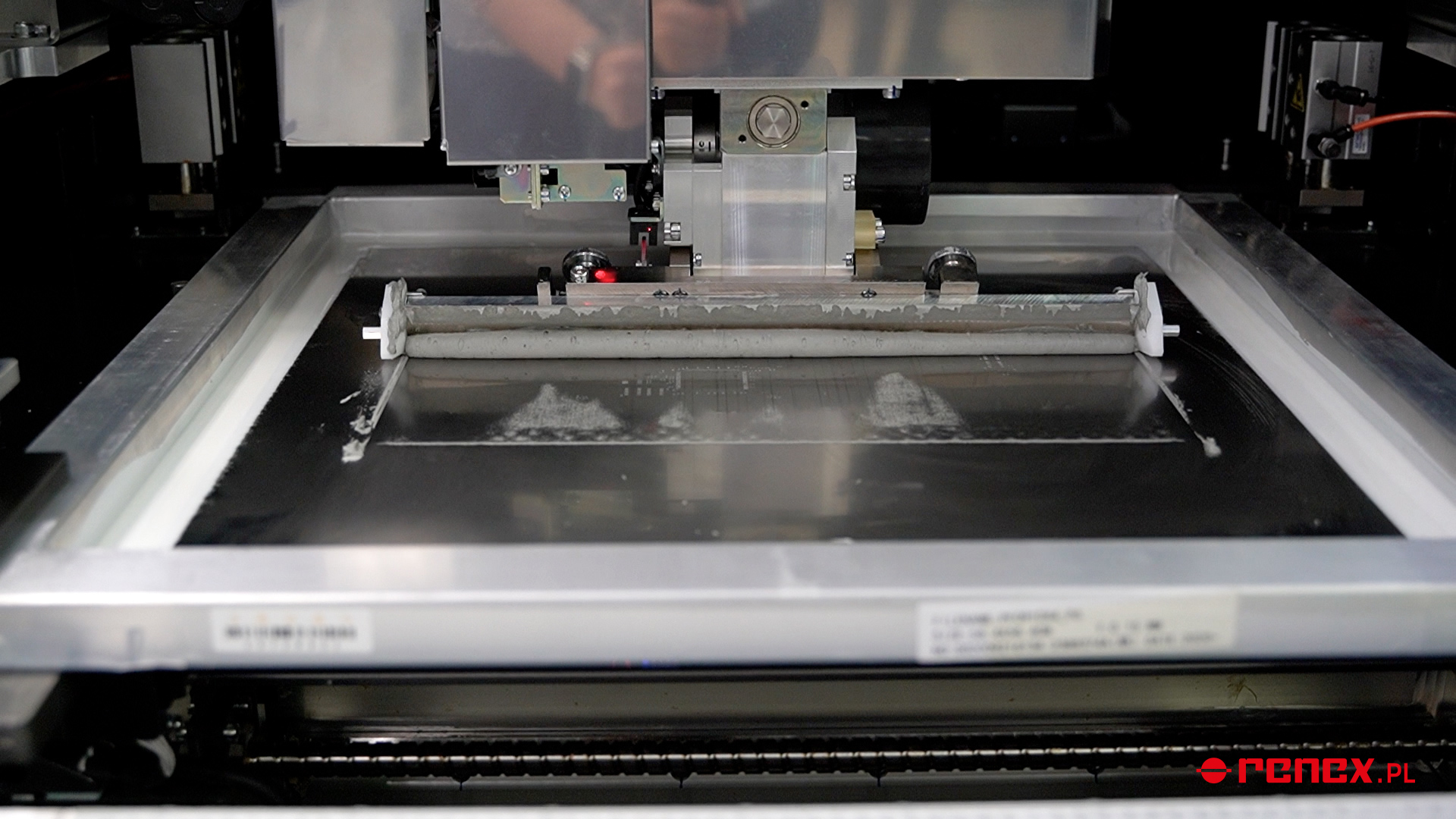

SIM, a company based in Lublin, has announced an increase in SMT production capacity thanks to its investment in a new production line including a YAMAHA YCP10 solder paste printer, YAMAHA YSM10 pick & place machine, and TWS1385 EVO reflow oven. In order to fully utilize the available production space, a REECO transport system was used, which allows

for non-standard L-shaped placement of the line.

Operating continuously since 1992, SIM Sp. z o.o. is an independent Polish technology company specializing in the design and production of solutions integrating the latest electronic and IT technologies. Full flexibility in the design of both hardware and software have earned the company the trust of entities in many sectors.

In recent years, it has become clear to us that our existing assembly capacity is insufficient for our company’s growth prospects. In 2020, despite the ongoing pandemic, we had a very strong performance in terms of contracts won and all indications are that these trends will only continue to strengthen. This showed us that it became necessary for us to equip our company with another – new production line. However, right at the start of the project we realised that our available production space would not be able to accommodate all of the equipment in a standard setting. However, in cooperation with our long-term business partner, the RENEX Group, we managed to find a solution. A complete production line based on top-class YAMAHA equipment and a reflow oven was somehow bridged with REECO angle conveyors to fit perfectly into the available space. This allowed us to increase the efficiency of the company by a whole line without the need for reconstruction or relocation. – commented Mr. Przemysław Podstawka – Director of the Production and Service Division of SIM Company of Engineers.

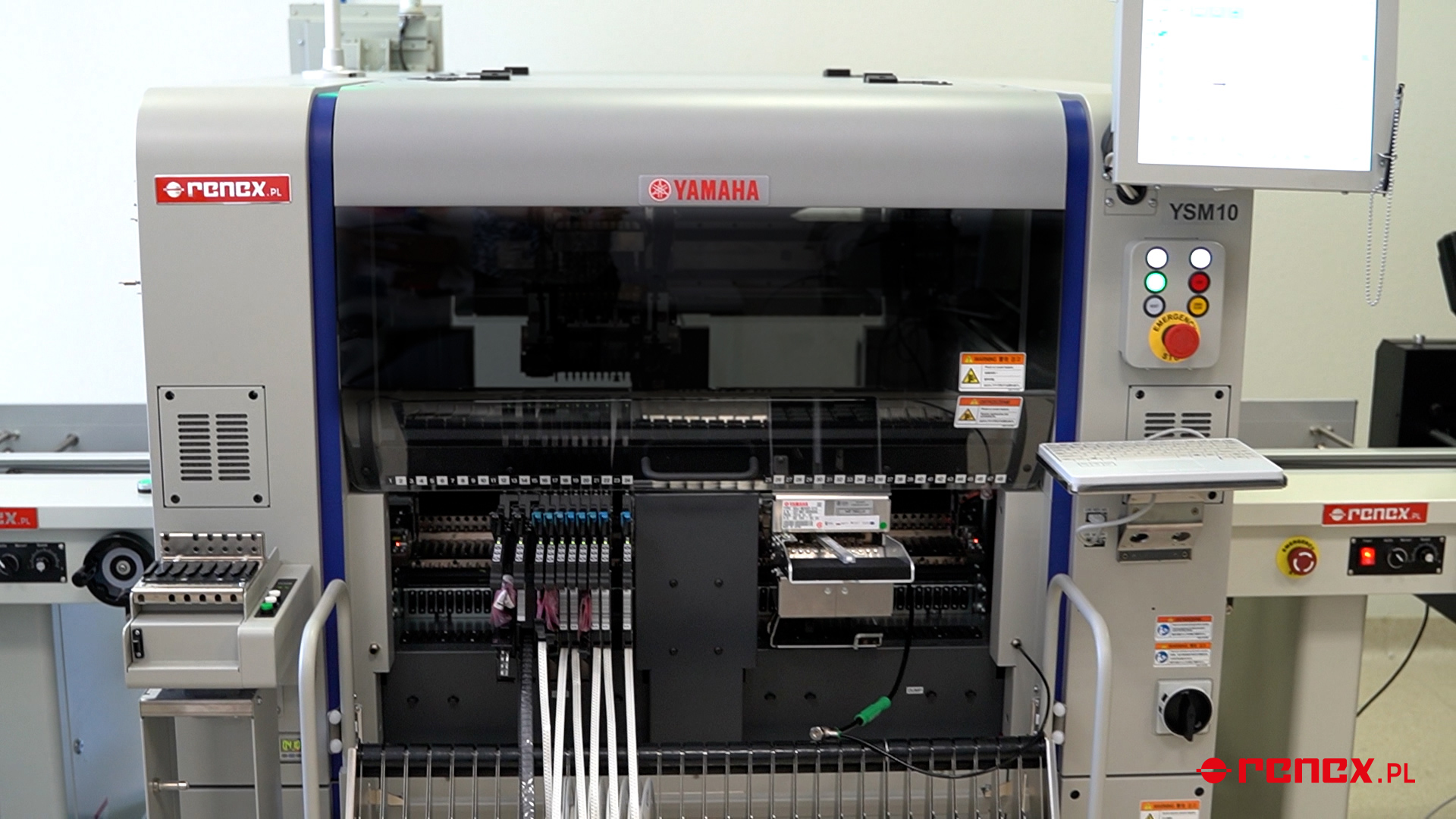

The YAMAHA YSM10 device used in SIM Company’s new line has been designed to guarantee the highest efficiency and precision under intensive operating conditions. It has a throughput capacity of up to 46,000 components per hour and a precision of ± 0.035 mm. Assembly can be performed on board sizes as big as 510×460 mm.

The machine is equipped as standard with a tape cutter at the front and back, which significantly helps in maintaining order and waste disposal. It is also possible to expand its functionality to include co-planarity verification, automatic settings recording, manual tray feeding system, multi-camera or UPS system.

We are happy to contribute to the success of our customers. We are happy to share our more than 30 years of experience in the electronics industry, the knowledge and competence of our engineers. Our technical and commercial advisors select equipment and solutions tailored to individual customer needs in order to optimize production processes. The key aspect of our business is the comprehensive support we provide to our partners – from consulting, through training, to the complete maintenance of the supplied equipment. commented Ms. Marzena Szczotkowska-Topić and Mr. Predrag Topić – owners of the RENEX Group.

About RENEX Group

RENEX Group is a company with over 30 years of experience, specializing in providing comprehensive support in the production of electronics packages. This includes extensive technical and commercial consulting, training and service. As part of this mission, the Group has developed RENEX TECHNOLOGY AND TRAINING CENTER, where partners and customers can select the right solutions, equipment and technologies for their needs with the help of RENEX experts and using complete production lines and DEMO ROOMs available on site. In addition to consulting support, the Group also specializes in the training field. It incorporates the largest AUTHORIZED IPC TRAINING CENTER in Central and Eastern Europe, which provides training in IPC standards and ESD protection. In addition, RENEX Group provides customized training in the proper operation and programming of production equipment and industrial robots as part of the YAMAHA AUTHORIZED TRAINING CENTER. This mission of providing comprehensive support is completed by a full range of maintenance and after-sales services, the level of which has recently been confirmed by the award granted by YAMAHA for the Best SMT Service in Europe.

Find more at www.renex.pl and www.sim.com.pl.