According to numerous test results, about 70% of damage to electronic components is caused by inadequate personnel protection. Losses in the production and servicing of equipment caused by electrostatic discharge in many companies are very serious, and often unnoticed costs. Workstations must be adequately protected.

ESD CLOTHING FOR ELECTRONICS

Paradoxically, the largest group of threats is caused by people. At the workstation, employees are almost always responsible for the accumulation of charges and the formation of electrostatic discharges. Most often the operator is not aware of his actions – he does not feel the discharge.

The values of potential electricity while performing activities at the workstation range from several hundred volts to even several tens of kilowatts, e.g. rising from a chair changes human potential by 1,5kV.

Discharges can therefore damage components and systems at the stage of their production, testing or servicing. The damage may appear only after a longer period of time or when adverse conditions occur. Electrostatic discharges can also cause damage to equipment or errors in programmable systems. Earthing is a necessary and always required method of protection against electrostatic discharges.

A grounding device, for example, could be a wristband. With this simple solution, the human being is connected to the grounding point and to the table mat, so that the sensitive elements on the mat are earthed and the charge on the human body is not produced.

However, it is a common mistake to believe that sufficient protection is only achieved by using a wristband. All international standards, including EN 61340-5-1, underline the need to use special ESD clothing directly in the workplace and in every EPA zone.

The basic element of protection is therefore special antistatic clothing with conductive fibres, which form a Faraday cage, providing protection against electrostatic discharges by suppressing static electric fields.

Jackets, jumpers, T-shirts, trousers, overalls – the choice of clothes on the market is very wide. When working with particularly sensitive systems, gloves with conductive fibres should also be considered. The outfit should be completed with shoes made of conductive material, which must remain in contact with an antistatic mat or a conductive and earthed floor to ensure full protection.

SELECTION OF CLOTHING

Depending on the scope of work, the choice of clothing must take into account at least a few basic factors: ensuring safety at work and protection of workers, meeting legal and company’s internal standards, taking into account specific working conditions, quality and production reliability.

Clothing maintenance and washing methods are also important. Especially for highly specialised clean room clothing, where clothing is one of the critical factors of process efficiency and safety requirements.

Finally, it is worth mentioning the need to take into account the dynamics of the wearer’s movements and ensure comfortable, long hours of work. Actually, defining the standards that clothing must meet is not an easy task, nor is it possible to present this subject in a short article. The only thing that needs to be mentioned is the need to base these decisions on an analysis of the work carried out in the company, and the identification of harmful and dangerous factors.

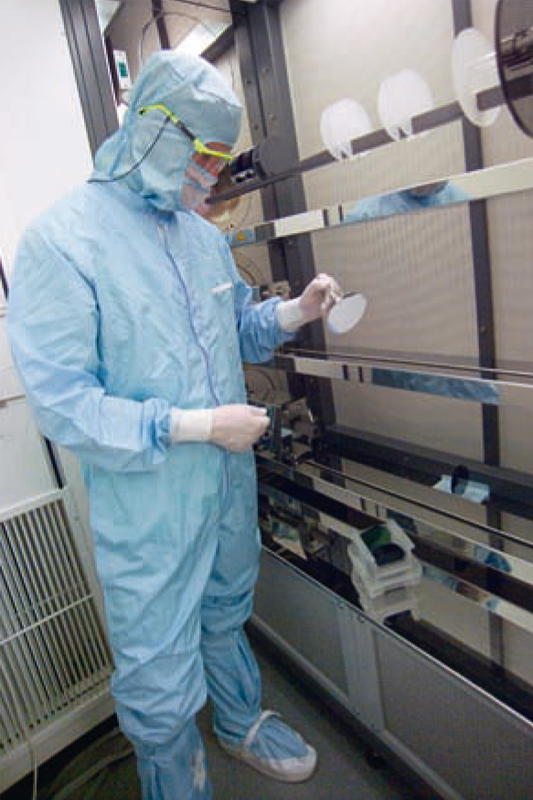

ANTISTATIC AND CLEAN ROOM CLOTHING

Clothing made of woven or knitted fabric with woven carbon fibre is an essential requirement for many applications. Work without antistatic clothing in the electronics industry most often cannot be carried out, as ordinary workwear causes the electrostatic charge to discharge into the application, leading to damage to the application, equipment and measurement disturbances. A separate category is clean room clothing. This is where protection against dusting will decide. A person entering the clean room in a specially prepared cloakroom must change into a complete outfit (not infrequently including underwear) consisting of a suit, a cap with a mask, gloves and shoes. Only then does he enter the clean zone through the airlock. As you can easily imagine, working in a suit for a few hours a day can become extremely unpleasant and can make movements extremely uncomfortable.

ECONOMY AND SENSE – RENTAL OF CLOTHING

Washing specialised clothing on your own is usually the worst of the solutions, and its drawbacks quickly become obvious. Above all, a worker in a domestic environment is not able to carry out the laundry in a way that ensures its continued proper functioning. Clothing will very quickly lose its antistatic properties, and certainly will not be able to be used in clean areas. The special washing process, which takes place in rooms with controlled environmental parameters, guarantees full monitoring of dust and dirt contamination, which is essential for the electronics, pharmaceutical, biotechnology and optical industries. Such conditions are only provided by laundries built in clean rooms.

Such a laundry operates also in Poland, and the level of cleanliness is controlled by a monitoring system in terms of air exchange rate per 1h, temperature, humidity, overpressure in the room and the number of particles of 0.3-5.0 µm.

Clean room clothing can be washed only in this standard and in controlled conditions according to ISO 14644 or GMP (Good Manufacturing Practice). Otherwise, the clothing will become dusty and its use in the clean zone will reduce the cleanliness class and reduce the effects of work.

Industrial laundry is usually combined with a rental service, not a purchase of clothing. It is a very beneficial service, popular for years with our western and northern neighbours, and in Poland it is becoming very popular for practically every kind of laboratory, protective and working clothes.

This was determined primarily by the efficiency and cost-effectiveness of this solution.

The system was constructed in such a way that when one piece of clothing was in use, the second one was available in a worker’s locker and the third one was washed (other variants are acceptable). Weekly replacements eliminate problems with dirty clothes or lack of them.

As the customer is not charged for the purchase of the clothes, but only for their rental combined with the laundry service, this solution is astonishingly advantageous, especially when compared to the purchase of clothes and the laundry detergent. In addition, the garments are serviced at all times, which means their professional repair and disposal. In such a cycle the clothes can be used in good condition for up to 5 years.

Clothing in this system is electronically supervised, customers can check online its condition, stage of use, cycle in circulation. We gain full control over an important piece of equipment and can eliminate most of the logistical and service problems, while reducing costs.