Single-axis robots are a popular solution to a wide variety of tasks in factories and logistics centers. Sometimes they operate as independent units, and often in groups coordinated by a central controller. However, the goal of their use is always to increase the efficiency, repeatability and consistency of operations.

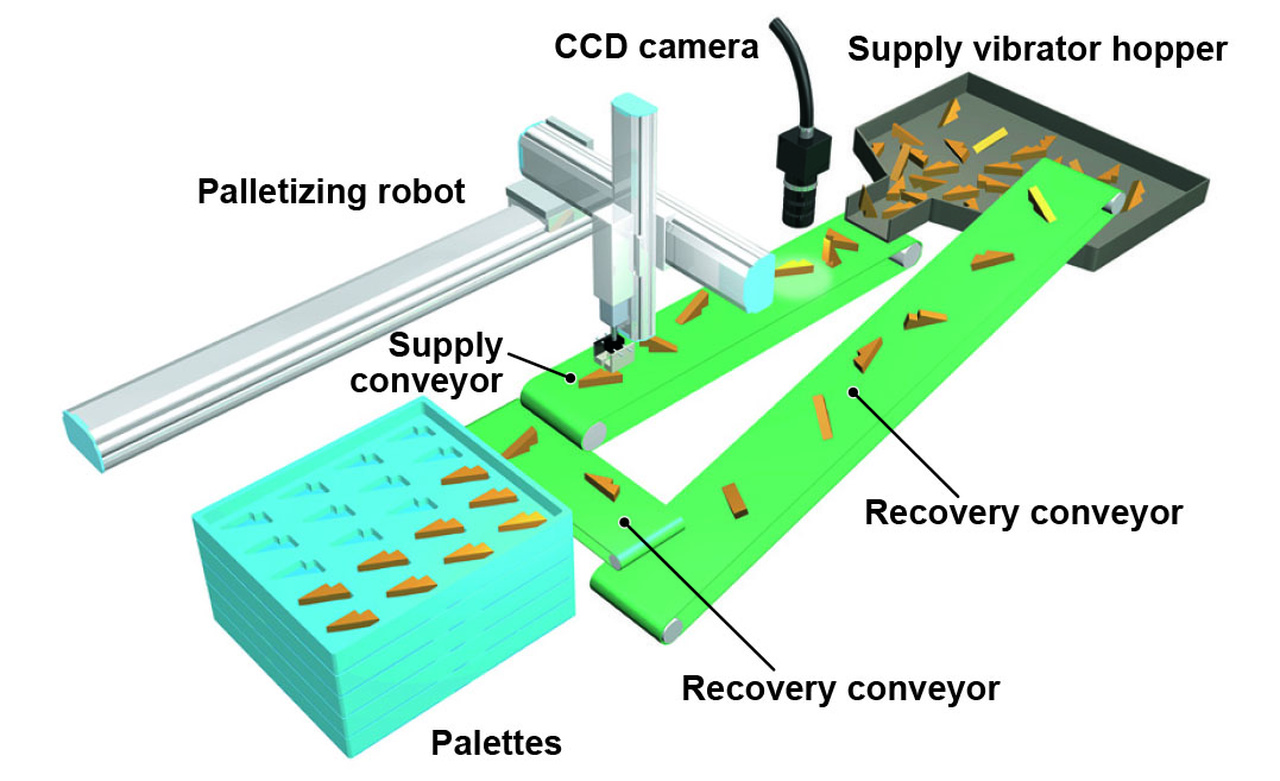

When looking for solutions to manufacturing problems, system integrators often develop systems based on single-axis, one-, two- or three-axis robots. They are used for tasks such as handling parts, cutting and positioning instruments and tools. Two or more linear units, on the other hand, can work together to perform tasks that require high accuracy, such as laser cutting, painting or dosing. By combining single-axis robots specially selected for each axis, a customized Cartesian robot can be built (Figure 1). YAMAHA also offers a range of standard Cartesian robots, available off-the-shelf. The linear unit can also work together with a Cartesian robot, connected to the same controller, in situations that require more axes.

A controller such as the YAMAHA RCX340 is usually chosen to manage the Cartesian robot. It has the ability to control one or more additional single-axis robots working within the same unified, coordinated system. This allows integrators to configure robots to handle complex sequences, with the flexibility to expand the system as needed.

What to look out for

Rigidity is one of the most important properties of a single-axis robot, necessary to ensure precise and repeatable positioning and to allow the carriage to move freely with minimal friction. Size and the ability to mount the robot so that it occupies the smallest possible space in the factory are also increasingly important factors. Using advanced design techniques, it is possible to achieve a reduction in dimensions while increasing rigidity in each axis.

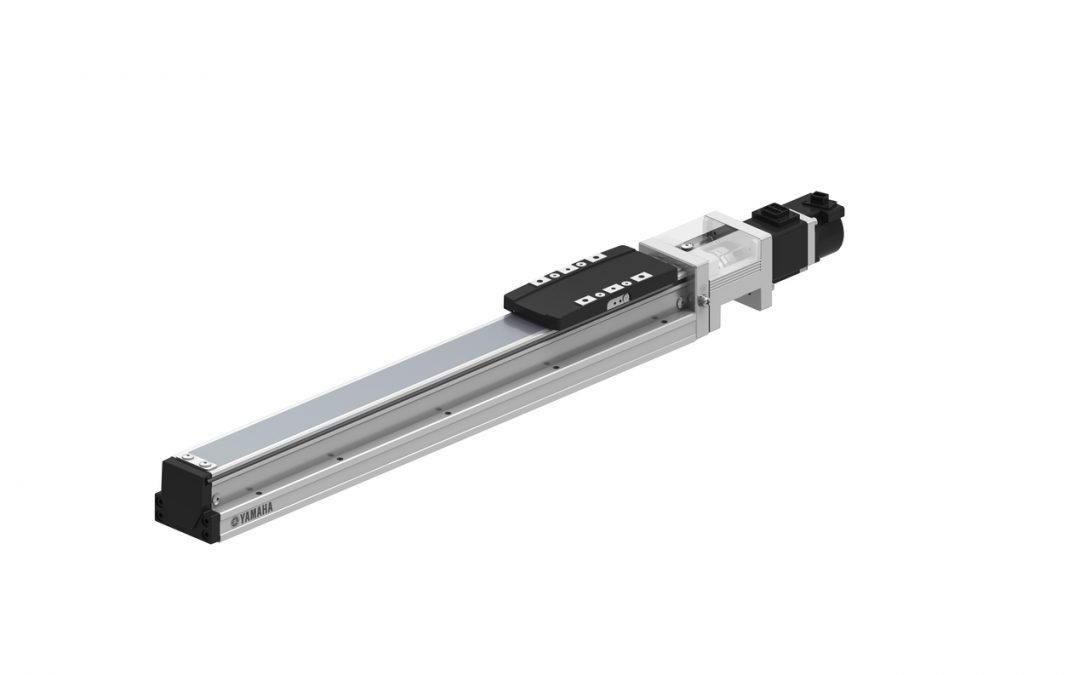

YAMAHA’s latest ROBONITY series of high-rigidity single-axis robots feature a one-piece design and a built-in linear guide. These improvements have increased rigidity by up to 300% while reducing rail width. The ABAR05 (Figure 2) is only 54 mm wide, a 17% savings over typical alternative models. No external guide is required, simplifying the design, and the increased rigidity keeps the robot’s lines uncurved when subjected to radial loading. Displacements in the direction of rotation are blocked, and tip-mounted tools achieve ±0° accuracy without rotation. The robots are available in stroke lengths up to 1100 mm.

Recent design improvements have also reduced the overall height. The main advantage of these new, slimmer robots is a lower center of gravity, which increases performance when used as the x-axis of a custom Cartesian robot. ABAS12 is 76 mm high and 120 mm wide. In addition, the latest design maximizes the motion stroke relative to the overall length. Reduced length, width and height, increased rigidity and a comparable range of motion compared to alternative models contribute to a significant reduction in overall size. Further space savings can be achieved in the design of the control panel. The EP-01 control panel for ROBONITY robots is 37% narrower than alternative modules, at 40 mm wide.

Choosing the right model

When choosing a single-axis robot, the type of motor should also be considered. YAMAHA’s ROBONITY series includes robots with a ground ball screw for use with a servo motor. There are complete units that can reach speeds of up to 2,400 mm/s. Also available are motorless actuators that are compatible with standard industrial motors up to 400 W. Mounting kits are available to change the orientation of the motor to suit the requirements of the application.

Alternatively, stepper motor robots, such as the Transervo series, provide a cost-effective solution with servo motor functionality for lower payload applications where top speed is not important. The latest models can handle nearly four times the payload of their predecessors, and the 1200 mm/s travel speed is 20% faster.

On the other hand, a single-axis robot with a linear motor may be the most cost-effective solution for applications requiring long-distance transportation of lightweight parts at high speed. Robots with a maximum stroke of more than four meters and a maximum speed of 2500 mm/s are available, with a position repeat accuracy of ±5 µm. Overall cycle time savings can be significant, and linear motors are quiet and suffer minimal wear. Typical payload capacity is several kilograms. Phaser MF linear motor robots equipped with jet magnets can transport objects weighing up to 160 kg at high speeds.

Simulation and configuration

When evaluating single-axis robots for applications involving one or more units, it’s also important to consider support tools for configuration and troubleshooting. YAMAHA’s online simulator helps select the optimal specification. Users can quickly calculate important criteria, such as expected cycle time and ball screw life, after describing a few basic parameters (Figure 3).

When setting up the system, the EP-01 robot controller works with the EP Manager PC application to help with analysis and configuration. Users can enter detailed information on operating conditions, including transport weight, point data and type of operation. Simulation provides all the necessary information, including total operating time, time to perform individual operations, maximum speed and acceleration.

When setting up and running a robot system in a manufacturing space, EP Manager provides important information such as real-time tracking of speed, motor load status and time to reach specific positions. Continuous monitoring is possible to verify settings and enable long-term analysis and troubleshooting assistance.

The tool also provides real-time tracking and allows checking the history of alerts to facilitate service. Previous data helps analyze errors by providing insight into parameters such as position, speed, operating conditions, current value, voltage and I/O status. Analysis of these various conditions can help identify the root cause of an alert. In addition, the real-time tracking function allows users to analyze the status up to the point of error, making it easier to identify problems such as motor overload.

The EP-01 controller generates a feedback signal on a dedicated channel separate from the standard network connection. This aids in analysis and monitoring by providing continuous, real-time position information that is independent of network communication delays. By providing real-time information about the robot’s current position, the feedback pulse also enables speed ripple compensation.

Special options

Special design features of the ROBONITY single-axis series include access to fixing points that allow quick and easy installation of any device from the top or bottom without removing any external parts. For applications requiring the shortest possible cycle time, ROBONITY AGXS models can accelerate/decelerate at speeds of up to 2g compared to conventional units, whose typical maximum speed is 0.5g. The AGXS (Figure 4) is an advanced series that uses ground ball screws for high accuracy and durability. The AGXS robots are ready to work in areas of high cleanliness, such as food preparation, cosmetics or pharmaceutical production.

They are equipped with stainless steel dust guards, and their low-friction rollers minimize grinding that creates dust and particles. A suction port is provided to safely remove foreign matter from the mechanisms. Single-axis robots provide an effective basis for integrating robots into automated processes. Their advantages include ease of selection, design and use. Key selection criteria include high rigidity, compact size and servo, stepper or linear motor drive for optimal acceleration and speed. Effective simulation and analysis tools can be an important factor in facilitating configuration and long-term maintenance.

What’s next?

YAMAHA and REECO equipment and robots can be seen and tested in action at the RENEX TECHNOLOGY AND TRAINING CENTER. Within this center, RENEX Group – which is one of the largest Polish companies in the electronics industry, as well as the distributor of YAMAHA Robotics for Poland and the Balkan countries – pursues its mission of providing comprehensive services to the electronics industry.

RENEX Group provides not only the equipment itself but also a wide range of consulting, service and training courses. RENEX TECHNOLOGY AND TRAINING CENTER specialists help identify production problems and select appropriate technological solutions. The Center also provides training in the field of introduced robotic solutions. Within the establishment there is an AUTHORIZED YAMAHA TRAINING CENTER providing expertise in the operation and programming of industrial equipment and robots, allowing users to take full advantage of their capabilities.