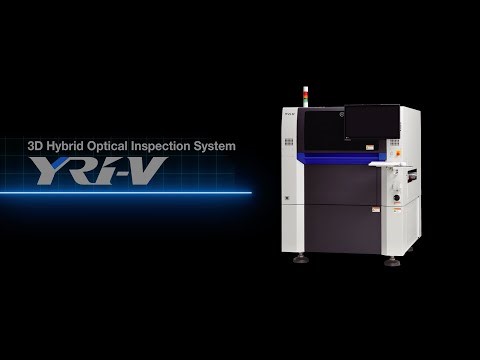

Automated visual inspection is essential in the industry, providing fast and accurate results. Improved AOI is one way that can respond to the need for fast inspection. Yamaha has introduced a new automatic optical control system YRI-V 3D model.

Miniaturization in Production

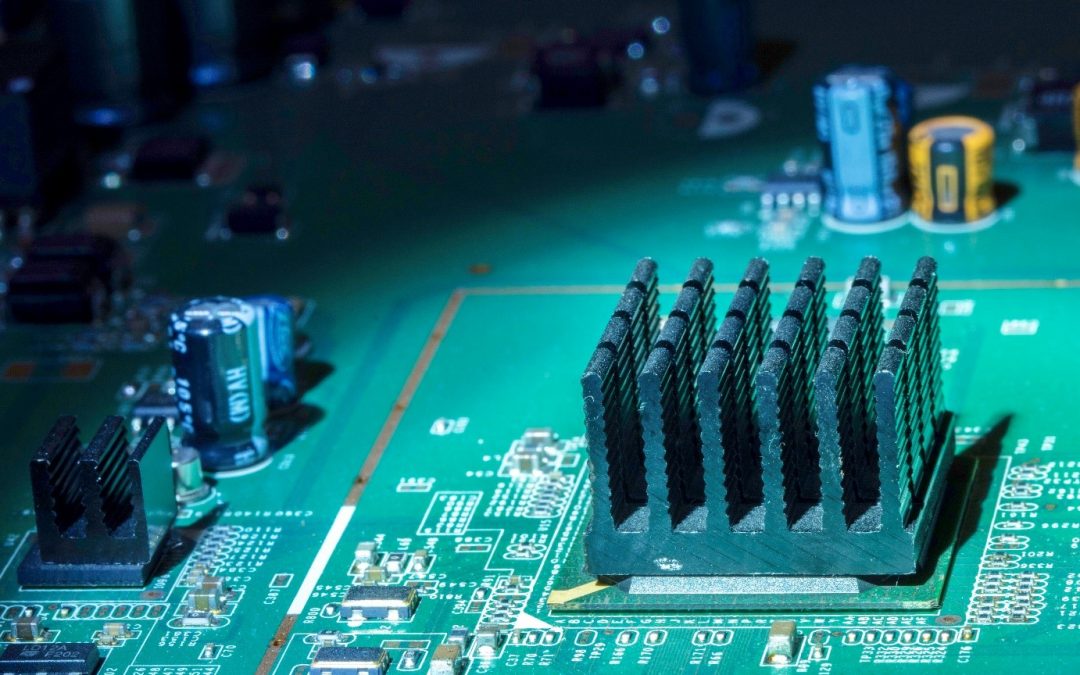

The increasing miniaturization has a greater impact on electronics production. Small parts and surface restrictions allow manufacturers to increase complexity and functions in smaller devices. Reducing device dimensions also increases their energy efficiency and performance, making them more cost-effective for consumers.

With the increase in complexity, electronics manufacturers must place more emphasis on quality. Greater complexity forces manufacturers to adhere to higher quality standards to ensure their products will withstand the stringent requirements set by consumers.

It’s becoming increasingly difficult for electronics manufacturers to produce products that will work flawlessly for a long time, making it crucial for both miniaturization and production quality to be equally high. AOI (Automatic Optical Inspection) is a popular solution for electronics manufacturers, especially in the case of miniature-sized components.

What is AOI?

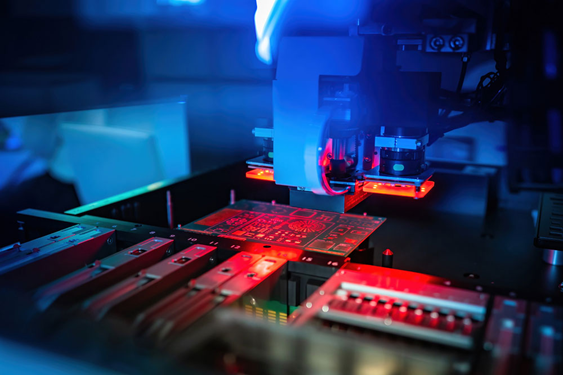

AOI (Automatic Optical Inspection) is an automated optical inspection that uses optical technology to detect product defects and non-conformities. AOI is used in many industries, including electronics, automotive, and food production, to enable fast and reliable detection of product defects.

AOI devices are equipped with digital cameras that record images of the product and a laser scanner that scans the product surface to detect defects. The systems then process the images and data to determine if the product meets specified quality requirements. If the system detects a non-conformity, it may stop production to minimize losses. AOI is widely used in electronics production and its main goal is to ensure the highest product quality possible.

AOI is utilized for the automatic detection and identification of production defects, ensuring high product quality. This technique is significantly more efficient and reliable than traditional visual inspection methods and is frequently used in industries where product quality is crucial. This allows manufacturers to reduce quality defects and helps in creating a higher-quality product. YAMAHA has developed an improved AOI model called YRi-V. The device is equipped with a new inspection head, which features a high-speed high-resolution camera, an upgraded 3D projector, and a powerful graphics processor. According to research conducted by YAMAHA Motor in 2021, YRi-V has the fastest inspection speed in the market. Additionally, it is capable of detecting subtle defects that were previously difficult to detect, including scratches, cracks, and nicks on surfaces that reflect light.

YRi-V, the new AOI model

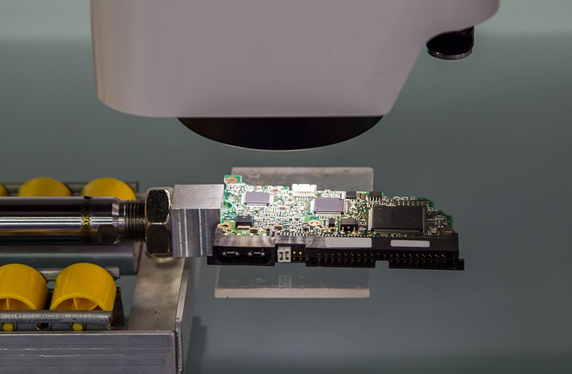

The YRi-V 3D system is designed to cater to the needs of fast production and increasingly smaller product dimensions. The system utilizes highly advanced visual algorithms to ensure fast, reliable, and accurate results. The model is equipped with highly efficient optical technology that provides quick and accurate results. The system consists of optical sensors that are equipped with a range of features such as high-resolution 3D visualization, highly efficient visual algorithms, and high-performance image processing.

The YRi-V new inspection head is equipped with 12 μm, 7 μm, and 5 μm resolution lenses, making it compatible with ultra-small components as small as 0201. The device is also equipped with enhanced luminance lighting and a high-speed high-resolution camera with a high frame rate.

Additionally, the new coaxial lighting increases the ability to detect scratches, cracks, and nicks, and the flexible handling of longer boards – with optional equipment – up to 1200 mm, and easier position adjustment for rails 2, 3, and 4 increase the ability to connect to other devices.

The YRi-V system is equipped with a range of features that make the product inspection process easier, including a user-friendly interface, automatic correction of positional deviation, and real-time display of inspection results.

Additionally, the use of a high-performance graphics processor provides faster image processing than previous models. This also allows for more precise inspections with a range of up to 25mm, as well as highly precise 3D inspections for 0201 elements and ultra-small integrated circuits with high-resolution imaging.

The new, intuitive graphical user interface, automation features, artificial intelligence, and other solutions make it easy for operators with limited experience to use. Additionally, CAD/CAM/YGX data conversion to inspection data is possible in one step, and Gerber data is compatible with the device by default.

The Yamaha YRi-V 3D is an example of new technology that meets the needs of fast production and product miniaturization. The system is a perfect solution for companies that want to take advantage of the benefits of automation and precise product checking while ensuring high performance.

RENEX GROUP – EXCLUSIVE DISTRIBUTOR OF YAMAHA SMT AND YAMAHA ROBOTICS

The exclusive distributor of YAMAHA SMT and YAMAHA ROBOTICS in Poland and Central and Eastern European countries is RENEX Group. Yamaha devices, including industrial robots, SMT production devices, SCARA robots, and other products from the RENEX offering, can be seen and tested in operation in the production line test conditions (also on own components and subassemblies) at the RENEX TECHNOLOGY CENTER and DEMOROOM. In addition to devices, the RENEX Group provides a comprehensive range of consulting and advisory services for the automation of production processes. Both SMT device and industrial robot programming and operation training are also conducted at the Center.

Summary

Automatic Optical Inspection (AOI) is a technology used to detect defects and non-conformities in products using optical technology. It is widely used in many industries such as electronics, automotive, and food production to ensure quick and reliable defect detection in products. Miniaturization is increasingly affecting electronics production, but as products become more complex, producers must focus on quality to ensure that their products meet consumer requirements. The new Yamaha AOI device model, YRi-V, enables new solutions in production.