YAMAHA Motor Europe has expanded its range of new equipment over the course of 2020, including two new SCARA robots, the LCMR200 series of modular linear conveyors and the RCXIVY2+ vision system.

In line with its policy of continuous development and improvement, YAMAHA has developed and introduced new economical SCARA robots, reinforced linear transport modules, and vision systems capable of recognizing irregularly shaped objects.

As emphasized by representatives of the RENEX Group, YAMAHA’s exclusive distributor in Central and Eastern Europe, the large number of new products is the result of YAMAHA’s emphasis on research and development as well as product improvement.

It can be seen that all of the changes in the new generation of units have been designed to increase their performance for the target customer. The range of applications is also being widened, making them even more suited to the changing nature of modern production lines.

SCARA YK-XE ROBOTS

Two new models in the SCARA YK-XE series have been introduced: the YK610XE-10 with an arm length of 610mm and the YK710XE-10 with an arm length of 710mm. The devices are based on the proven technology of the current YK-XE series with a maximum payload of 10 kg and a standard cycle time of 0.39 seconds (YK610XE-10) or 0.42 seconds (YK710XE-10).

With the 400mm arm length SCARA YK400XE-4 robot introduced late last year, the YK-XE series now includes three models, giving an even wider range of applications – from handling and sorting small components in manufacturing such as smartphones and computers, to working with large components such as those used in home appliances and the automotive industry.

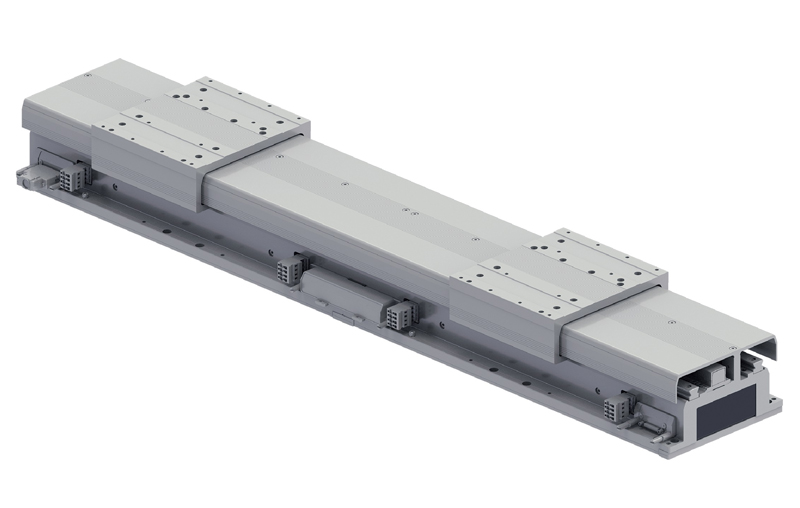

LCMR200 LINEAR CONVEYORS

YAMAHA has recently introduced the LCMR200 series of linear transporters. The designers have maintained the high accuracy and short stroke characteristic of the previous LCM-100 model, but have improved the module design. The linear guide and carriage rail have been enlarged and strengthened, while keeping the overall size the same. The result is a more robust model that is better suited for environments where foreign objects and static noise are present.

The system allows up to 64 carriages (sliders) to be supported by a single YHX controller, and by creating a new programming model using the Standard Profile, the need to program individual controller events is eliminated. This greatly simplifies the integration process.

RCXIVY2+ VISION SYSTEM

Another of YAMAHA’s new additions to the market is the new RCXiVY2+ vision system, which is capable of detecting irregularly shaped objects and is therefore suitable for applications in the food, pharmaceutical, cosmetics and apparel industries, among others. The system is equipped with a new high-performance camera, and thanks to its enhanced data processing capabilities, its recognition time is up to 45% faster than the current iVY2 model.

The new model is also fully integrated with robots by incorporating vision, lighting and tracking control cards into the RCX3 series robot controller. This change enables robot control, image processing, lighting control and conveyor control from the robot program, significantly reducing setup time.

YAMAHA SOLUTIONS FOR REECO ROBOTS

YAMAHA SCARA robots have been successfully used for many years in REECO Robots – universal, ready-to-work robotic workstations that can replace humans in tedious, precise and repetitive tasks. Available devices allow the implementation of tasks such as soldering, twisting, dosing or labeling, as well as other – non-standard at the customer’s request. The devices are designed to be implemented with the least possible effort into an already operating production line. Two robots or more can form cooperating teams or work together with other machines and loading and unloading stations.

DISTRIBUTION IN POLAND

RENEX Group is the exclusive distributor of YAMAHA SMT and YAMAHA ROBOTICS in Poland and countries of Central and Eastern Europe. YAMAHA devices, as well as other products from the RENEX offer can be seen and checked in operation in the test conditions of production lines (also with own components and subassemblies) in the RENEX TECHNICAL CENTER and DEMOROOM. Apart from the equipment, the RENEX Group provides a comprehensive range of consulting and advisory services in the field of automation of production processes. The Center also conducts training in programming and operation of both SMT devices and industrial robots. If you are interested, please contact RENEX Group Technical and Sales Consultants – dth@renex.pl.