RENEX Group has announced that it has developed and is introducing a new model in the REECO Robot series,

the REECO RE-2500 Coating Robot, which is designed to apply conformal coatings. The device was developed

as part of the research and development of RENEX TECHNOLOGY AND TRAINING CENTER.

REECO robots are a series of production devices which are fully automated, independent units that can be implemented into an existing or newly created production line. The series has been awarded TERAZ POLSKA title.

Robots in the range so far include REECO Soldering Robot, well known in the electronics service manufacturing industry, and models: Dosing, Screwdriving and Labeling, designed for various types of manufacturing and service operations. RENEX Group also develops customized robots for individual customer orders.

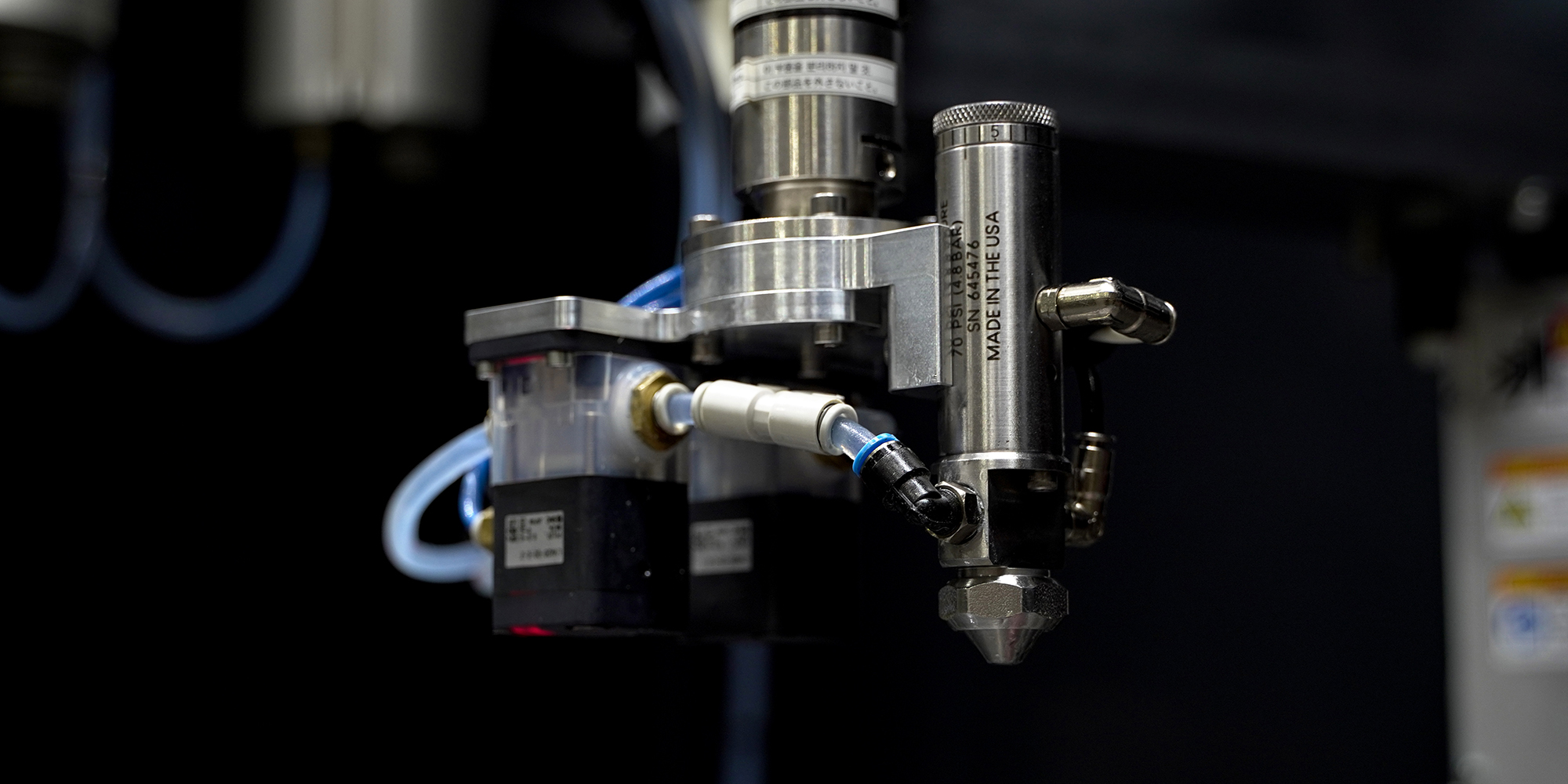

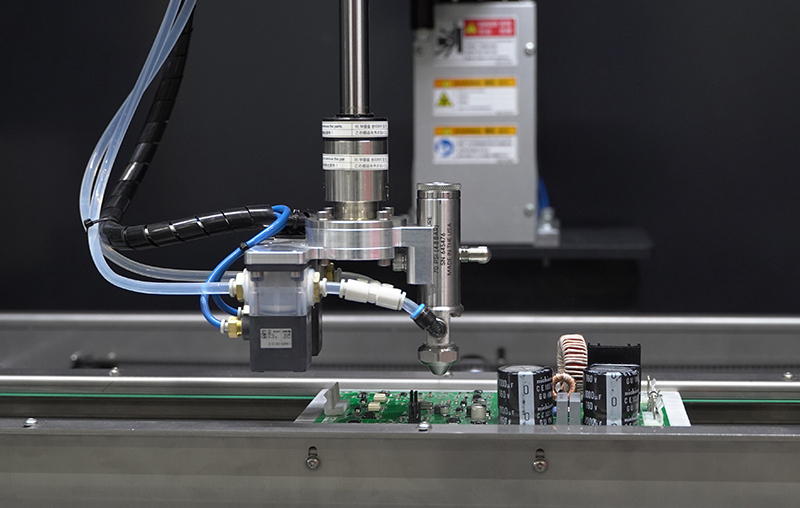

The new model, REECO Coating Robot, has been developed to automate a production step involving the spray application of fluids. This includes, in particular, the application of various types of coatings, including conformal coating often used in the electronics manufacturing industry. The machine is equipped with a nozzle valve that ensures uniform application of liquid coatings with low to medium viscosity and an integrated nozzle flushing system that eliminates the problem of manual cleaning of the valve.

The device – similarly to previous models in the series – has been based on a design and safety cage developed by RENEX Group. This allows the introduction of new functionality while retaining the previous advantages of the system. The robot can work as an independent unit (offline) supporting e.g. non-automated production processes, or it can be a part of a production line (in-line). By using an edge conveyor and the SMEMA communication system, it is possible to integrate several REECO robots and to connect them to machines from other manufacturers in no time.

The new model in the REECO Robot series, developed at our RENEX TECHNOLOGY AND TRAINING CENTER, is a big success for our R&D team. We see that conformal coating of PCBs is an increasingly frequent technological requirement for EMS companies. Nevertheless, due to the lack of simple and low-cost solutions, it is very often still a manual process. We hope that by providing a ready-to-run, inline device we will make it easier for our partners to solve this problem. At the same time we see a great potential for the new model to be used in other industries and types of production, as a device that allows the application of many types of liquids with different viscosity – such as paints or varnishes. — commented Mrs. Marzena Szczotkowska-Topić and Mr. Predrag Topić – owners of RENEX Group.

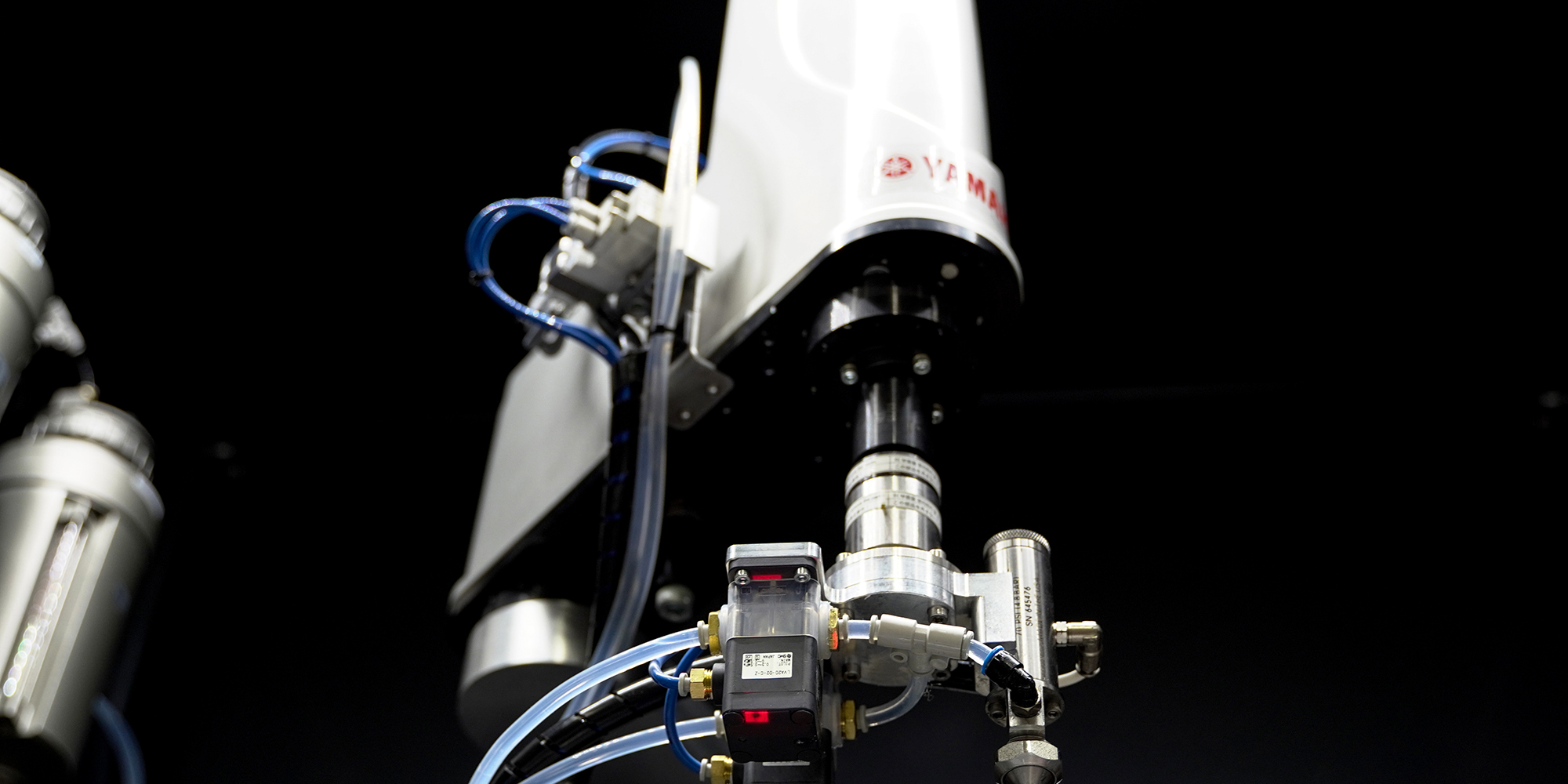

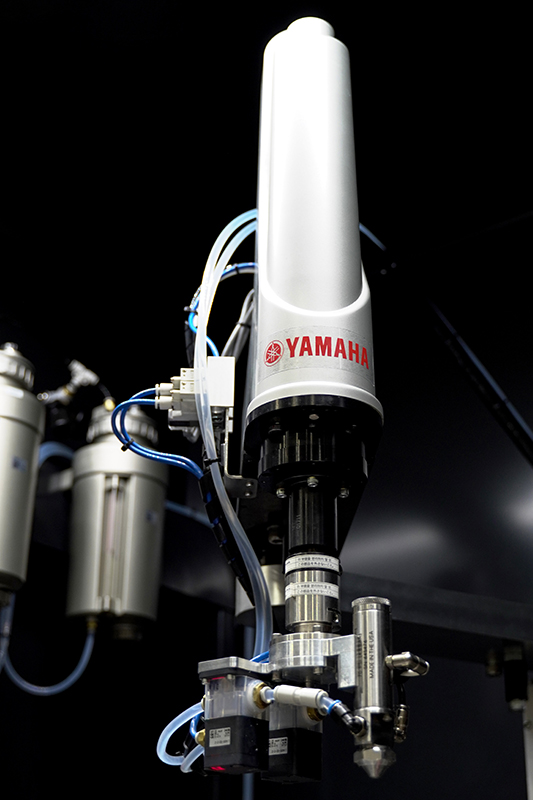

As with the other models in the REECO Robot series, the newly-developed device uses a YAMAHA SCARA arm, which, among other things, guarantees the highest degree of repeatability, speed, and reliability due to its beltless design and high-quality workmanship. Moreover, the process parameters are controlled by a Siemens PLC.

RENEX Group, which developed the REECO robot line, is also a partner and distributor of YAMAHA industrial robots and SMT production line equipment in Poland and the Balkan countries.

Within the framework of cooperation at the RENEX TECHNOLOGY AND TRAINING CENTER, an AUTHORIZED YAMAHA TRAINING CENTER was established, where training in the operation and programming of robots and industrial devices is conducted. This includes SCARA robots, transport systems, and vision systems.

Training in this area is aimed at robotics and automation integrators, representatives and students of technical universities and engineers involved in service and maintenance.

You can see and test the equipment offered by RENEX in operation – even with your own components – at the RENEX TECHNOLOGY AND TRAINING CENTER.