What equipment should future professionals and explorers train on? After all, you cannot entrust a “rookie”, e.g. a racing machine; however, on the other hand, on a standard old car they will never know what car sport is all about.

The problem seems to be important also in relation to students studying in electronics-related professions. There is a natural contradiction between the increasing demands of employers and the financial possibilities of schools. The former operate in a very difficult market, which forces the use of modern devices, instruments and tools and hiring staff able to handle and use them effectively. Education, on the other hand, suffers from problems resulting from underfunding.

Electronics – a modern, future-oriented field – has experienced a strong shock in Poland when confronted with the free market economy of the world. Despite the difficulties, however, it is in a much better position than the industries not so long ago, and today practically doomed to extinction.

Although many ambitious undertakings have fallen and the chosen directions and methods of development have to be abandoned, electronics is an area with good prospects for the future. One of the conditions for competitiveness is high labour productivity, which, however, is influenced by a number of factors, among which the level of training of the employees is important.

This is a problem whose solution depends in part on the companies themselves and in large part on the level of education in schools. Employers would like to devote as little resources as possible to the implementation of the employee to perform the entrusted activities independently, efficiently and responsibly. This is why job offers so often include the condition: required experience in a similar position. This condition, which is the cause of the graduates’ bitterness, is in its essence a vote of no confidence, expressed in relation to the level and practical usefulness of knowledge and skills acquired from schools.

In addition to knowledge of modern technologies and system solutions functioning within his specialty, an electronics technician should demonstrate knowledge of the currently used measuring methods and instruments, as well as practical skills of using modern devices and tools during the design, implementation, production, diagnostics and repair of the currently used equipment.

The curriculum includes a number of practical classes in workshops and laboratories, but there is still the question of adequate equipment for the classroom. The workstation for learning measurement and control techniques, assembly of electronic components and systems, or diagnostics and repairs, should be similar to a professional one, at least in terms of basic parameters and capabilities, so that the skills and habits acquired during the classes can provide a solid basis for taking up more difficult tasks efficiently. It should set a good example in terms of ergonomic and safety solutions: enabling a healthy, fatigue-free posture, facilitating sequences of activities, ensuring proper lighting and eye and noise protection, as well as protection against harmful chemicals.

The standard solutions, based on a modular construction, covering the workplace and its surroundings (tables with lighting, worktops, shelves, cabinets, containers, carts) are offered by REECO. Ergonomic antistatic esd chairs, designed for industrial or laboratory applications, are REECO’s speciality. Single and multi-position absorption and filtration systems can be selected from the extensive PACE offer. Tools, even the simple ones, should guarantee not only safe but also comfortable use.

The tooling must be complete and used for its intended purpose – rewarding creative, unconventional uses is not acceptable. Working with good tools is effective and enjoyable, and for those who are not yet skilled, better tools are – instead of frequent failures, leading to discouragement – quick progress, satisfaction and better motivation for further training.

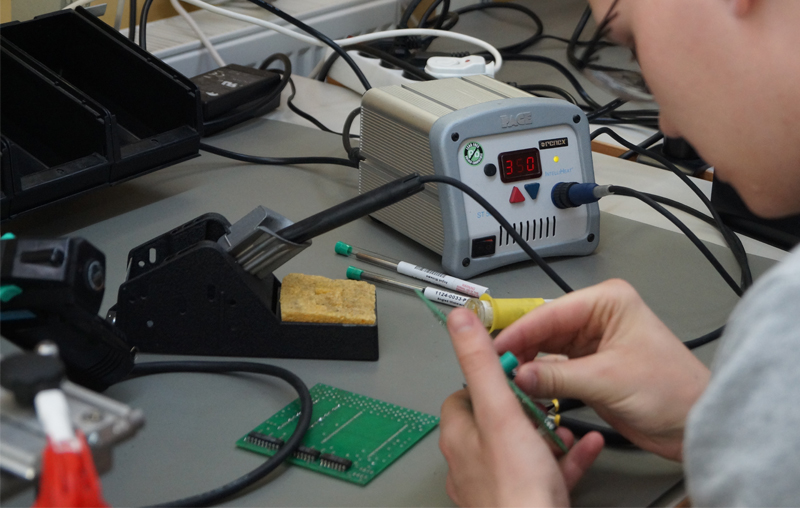

In the professional practice of electronics, the most frequently used tools are: devices for assembly/disassembly of elements and systems, i.e. more or less advanced soldering stations with appropriate tooling, various pliers, cutters, screwdrivers, tweezers and tools for stripping wires.

It happens that young electronics engineers underestimate their importance by focusing on data processing in processors, programmers, controllers, avoiding contact with the physical, “tangible” side of technical reality. In the educational process, therefore, the role it plays, the problems and requirements of the hardware must be well presented. For teaching purposes, it is good to have a soldering station with the ability to assemble and disassemble most of the components and electronic circuits encountered – from the THT ones (also in multilayer circuits with metallised holes) to SMD. The SMD integrated circuit (e.g. PQFP) can be mounted using a simple soldering station with a handle equipped with a special “mini wave” type tip (PACE).

The science of soldering with the hot air blowing (reflow) method, using soldering paste, requires a compressor unit. Such a solution further significantly extends the disassembly possibilities. Nevertheless, when buying a soldering iron for the applications under consideration here, one has to reach for equipment from a higher shelf than that occupied by popular transformer soldering irons. Similarly, when buying the above mentioned hand tools, it is better to take advantage of the offer of well-known manufacturers with established reputation, such as Lindström, Piergiacomi or BAHCO. Brand products are safe and comfortable, they are also distinguished by their high durability, which may be particularly important due to the possibility of improper use and frequent use of the tool in an untrained manner. Before making a choice, it is worth examining what devices and tools are used by companies that are potential employers for graduates of a given school and try to effectively introduce students to the technologies used there.

Complementarity of the vocational education offer with the needs of the economy is important and desirable. Assistance in choosing a development path that takes into account the widest possible range of issues is available today; high quality devices, tools, equipment, accessories and materials from renowned manufacturers are also available – their representatives guarantee rational completion, training and service care.