The introduction of a small-batch and prototype SMT production line is a key element in verifying device design before commencing mass production. The quick and accurate execution of prototypes is an integral part of the process, bridging the R&D department’s design phase to the final product reaching the market. Modern, efficient, and cost-effective solutions allow companies to establish an independent SMT assembly infrastructure

Implementing an electronic package for mass production is a complex and time-consuming task. The miniaturization of components often limits or even precludes manual assembly, necessitating the use of advanced equipment for prototype creation. Small-batch production demands flexibility and speed, which can be constrained when outsourcing to specialized EMS companies. An alternative is investing in in-house assembly equipment, which grants full control over the production process and independence from external entities.

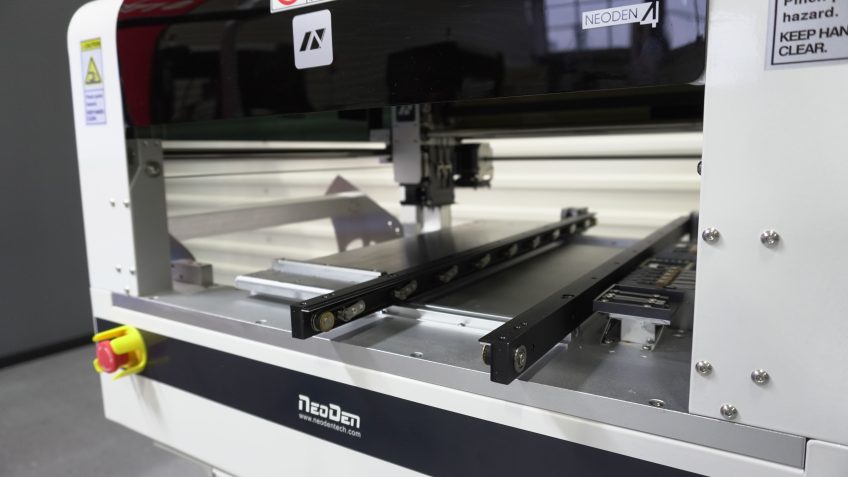

RENEX, leveraging years of experience, has introduced a complete set of NEODEN assembly equipment, enabling cost-effective creation of hardware infrastructure tailored to small series and prototypes. The package includes two models of manual stencil printers (FP2636 and FP2636F), the NEODEN 4 pick-and-place machine, and the IN6 reflow oven. The compact size of these devices allows for installation without requiring major production space reorganization.

NEODEN manual stencil printers are available in two variants: the FP2636 for frameless stencils and the FP2636F for framed stencils. These devices replicate the precise solder paste application process typical of inline SMT printers while requiring minimal financial and spatial investment. Both models are compact—measuring 660×470×245 mm—making them suitable for placement directly at an operator’s workstation. Despite their small size, they accommodate boards ranging from 10×5 mm to 250×350 mm, allowing for prototype and small-batch production of most standard designs.

The next step in the SMT process, after solder paste application, is component placement—performed in production lines using pick-and-place machines. For small-batch and prototype production, this task can be executed using the NEODEN 4 pick-and-place machine. Equipped with four heads and a vision system, the device handles components as small as 0201 using tape, vibrating, or tray feeders and places them precisely with a throughput of 4,400 CPH (according to IPC 9850 standards). A large working area and transport system enable handling boards up to 350×400 mm in size, expandable to 310×1500 mm.

As in mass production, the prototype line’s final stage is completed with a reflow oven. Within the NEODEN product family, the innovative IN6 model is available. This four-zone device provides full process control and features a touch screen and graphical display showing real-time process data. An additional thermocouple allows for optimizing the thermal profile for specific projects. The oven starts up within 15 minutes, and its unique aluminum heaters ensure even heat distribution, reaching reflow temperatures of up to 300°C. Its conveyor system transports boards with adjustable speeds ranging from 15 to 60 cm/min over a process length of 680 mm. The device also includes an internal fume filtration system, a critical feature for small prototype production spaces typically lacking central exhaust systems

RENEX offers the opportunity to view and test NEODEN equipment at their Technology and Training Center and Demo Room. Customers can evaluate the equipment using their own components, providing a precise assessment of its capabilities. The center also provides training on programming and operating the delivered devices, further supporting companies in fully leveraging their investment.

Investing in a small-batch PCB production line yields returns through time and cost savings, offering complete operational flexibility and high-quality PCBA manufacturing. The small dimensions of the equipment make installation feasible even in standard office spaces, significantly enhancing scalability. Supported by RENEX’s service and technical-commercial advisory, the NEODEN offering perfectly addresses the needs of modern enterprises, enabling growth and increasing profitability.

In summary, building an in-house prototype production line is becoming an industry standard. NEODEN devices offer companies not only savings and flexibility but also top-tier quality and production process safety.