SCARA robots are used in industry to automate and increase the efficiency of Pick&Place processes and small assembly processes such as screwdriving, dispensing or moving components between processes. Recently, applications in which they perform functional tests — such as pushbutton activation — are also popular.

Like any previous process automation technology, robotization must provide added value by increasing productivity and reducing costs for its owners. In any industrial project, speed and timing must be carefully monitored, as well as accuracy, repeatability and reliability, to ensure a satisfactory return on investment.

It can be seen that at the same time the performance and functionality of SCARA robots is moving forward. New designs allow smaller robots to perform increasingly heavy tasks, maintaining high speeds and short cycle times. Vision systems now work as plug and play, which further simplifies installation and programming. In addition, new solutions are introduced to reduce mechanical wear and tear and improve maintenance. We can analyse these changes by looking under the cover of modern SCARA robots.

MOTION AND BALANCE

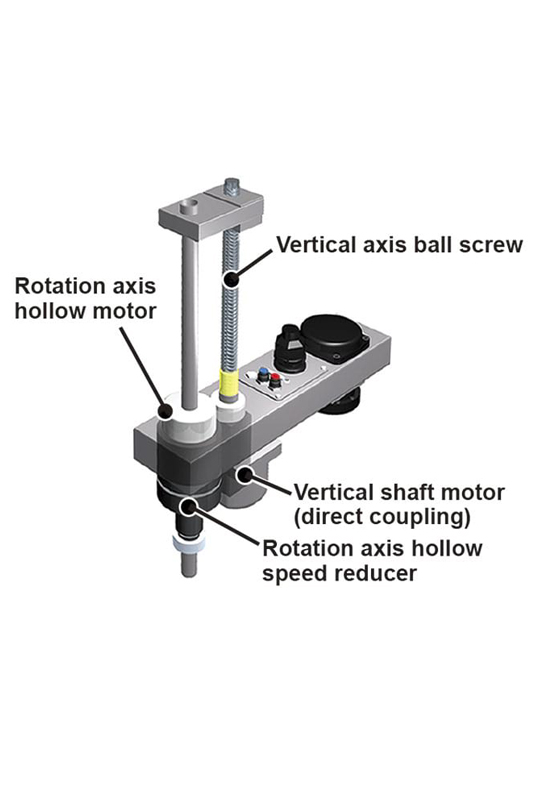

Innovations to improve control over the motion of the tip help to increase both speed and positional accuracy. Pick and place processes demand well controlled vertical, or z-axis, movement as well as rotational, or R-axis, movement. Traditionally, z-axis motion is handled using a lead screw driven by the vertical shaft motor, while the R-axis is belt-driven from the rotary shaft motor.

Both belt drives can be replaced by direct drives, which eliminates problems of belt aging, stretching or cracking, and consequently increases precision and eliminates the need for maintenance and regular belt changes. YAMAHA has developed a direct drive with a ball screw for beltless Z-axis control.

Yamaha developed a direct ball-screw drive mechanism for beltless z-axis control, leveraging its experience with single-axis robots, as well as a combined hollow motor and coaxial speed-reduction gear that delivers several advantages for R-axis motion control.

In addition, optimisation of driving-gear ratios help achieve the fastest possible rotational speed and x-y motion throughout the working area of the machine, resulting in lower cycle times. This is especially important for processes that involve transferring objects over large distances.

Current SCARA robots featuring beltless drive cover sizes up to about 1200mm arm length and about 50kg maximum payload. Smaller models down to about 120mm and 1kg maximum payload allow users to configure high-performing space-efficient assembly cells that occupy a small factory area.

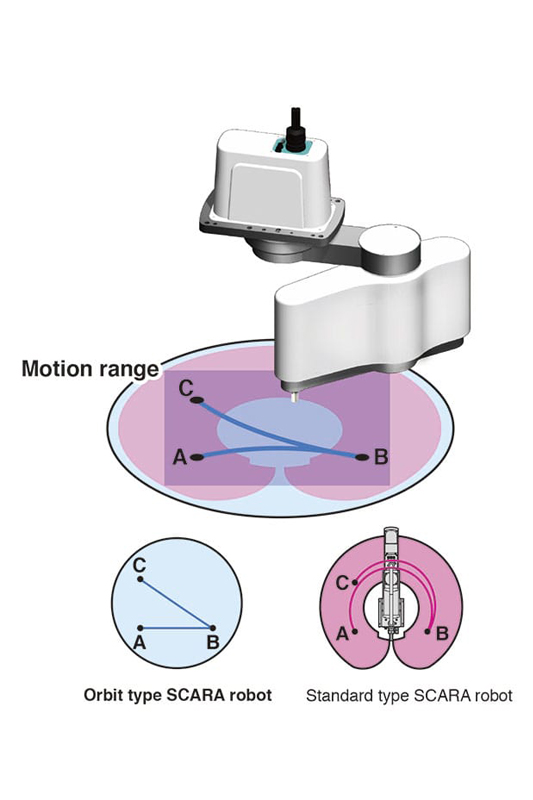

Where factory space is especially tight, ceiling-mounted orbital SCARA robots can reach any location within the work envelope below allowing extra freedom to minimise the process footprint. With orbital SCARA robots, optimal weight balance is key to achieving high excursion speeds with a large payload capability. Yamaha utilises lightweight materials and leverages its hollow motor and gear knowhow, combined with optimised internal motor positioning, to achieve a standard cycle time for moving a 1kg load 300mm horizontally and 25mm up/down to just 0.29 seconds, which is about 36% faster than preceding models.

The maximum payload is 5kg. A further advantage coming from superior balance and lower inertia is a reduction in stresses exerted on the mounting frame that must be installed to carry the robot. This allows a lightweight, simplified design that saves cost and eases installation in the factory.

INNOVATIONS FOR UPTIME

Long-term positioning accuracy and immunity to environmental contaminants such as moisture, dust, and grease can be enhanced by replacing optical encoders with magnetic resolvers for position sensing. Magnetic resolvers are inherently immune to shocks and electrical noise that can interfere with optical encoders. The magnetic resolver benefits from simple construction with minimal electronic components, ensuring greater reliability and high-temperature performance.

In addition, careful attention to simplifying maintenance can have a valuable effect on increasing equipment uptime. Designing panels for easy removal without needing to detach wiring or pipework allow essential servicing or repairs to be completed quickly. In addition, the latest long-life grease formulas eliminate time-consuming disassembly and lubrication for the lifetime of the equipment.

PLUG&PLAY VISION

Adding vision expands the range of functions the robot can perform to include searching for workpieces and correcting for position deviations. Historically, machine vision has been controlled separately from the robot, requiring specialist vision knowledge to program the vision system and utilise the data in robot instructions. The latest vision systems eliminate this barrier, integrating vision within the robot program to enable plug-and-play operation and greatly reduced startup time. Communication lag between the vision and robot systems is also eliminated. Yamaha’s iVY2 vision system and RCX340 controller further enhance performance with innovations such as a new CTMOVE command that executes a complete conveyor-tracking cycle from start position to component pickup, which replaces three separate instructions to enable pick and place at up to 100cpm.

SPECIAL REQUIREMENTS

Finally, novel configurations can be considered to satisfy special requirements. Inverse type SCARA robots are specially designed to raise the workpiece from below, which prevents contamination by falling particles such as dust or moisture that may gather on the surface of the robot.

Clean-room SCARA robots are also available, benefiting from beltless operation that eliminates contaminants due to belt deterioration and featuring built-in suction at the rear of the machine to prevent dust emission.

LATEST MODELS

At this point it is important to mention the latest robots from the YAMAHA range: SCARA YK610XE-10 with an arm length of 610mm and YK710XE-10 with an arm length of 710mm. Both robots are launched on 16 April 2020. The two new models are based on the proven technology of the current YK-XE series with a maximum payload of 10 kg and a standard cycle time of 0.39 seconds (YK610XE-10) or 0.42 seconds (YK710XE-10). Together with the SCARA YK400XE-4 robot with an arm length of 400mm launched at the end of 2019, the YK-XE series includes three models, providing a wide range of applications — from handling and sorting small components in the production of e.g. smartphones and computers to working with large components such as those used in household and automotive equipment.

It should be added that this first XE-series robot — SCARA YK400XE-4 with an arm length of 400mm — is now offered by YAMAHA Motors in a set with a state-of-the-art RCX340 controller at a limited time price offer. The promotion also includes sets in an alternative option with another SCARA unit — the renowned YK400 XR model with an arm length of 400mm and a working load capacity of up to 3kg. More information about the new models here: https://tinyurl.com/YK-XE-XR

CONCLUSION

SCARA robot design is improving in many subtle ways, all the way from the rotary tip to the controller interface, to increase performance, speed and reliability, enabling higher productivity and faster return on investment.

YAMAHA robots and other equipment from the RENEX Group’s range can be viewed and tested in operation in the RENEX TECHNOLOGICAL CENTRE and DEMOROOM.