IPC standards – widely adopted in the industry of production and service of electronic packages determine the optimal value of relative humidity in which the components and PCBs should be stored at 5% (RH – Relative Humidity). It follows that the elements sensitive to moisture – MSD – should (having been removed from the protective packaging) be stored in an environment where there is only 5% of water vapor in the air, in relation to the amount that would potentially saturate the air at a given temperature.

Storage of components in an environment with higher humidity is associated with the risk of their corrosion (in particular leads), as well as, which may have far-reaching consequences, violations by the factory of the IPC standards in which the order was contracted.

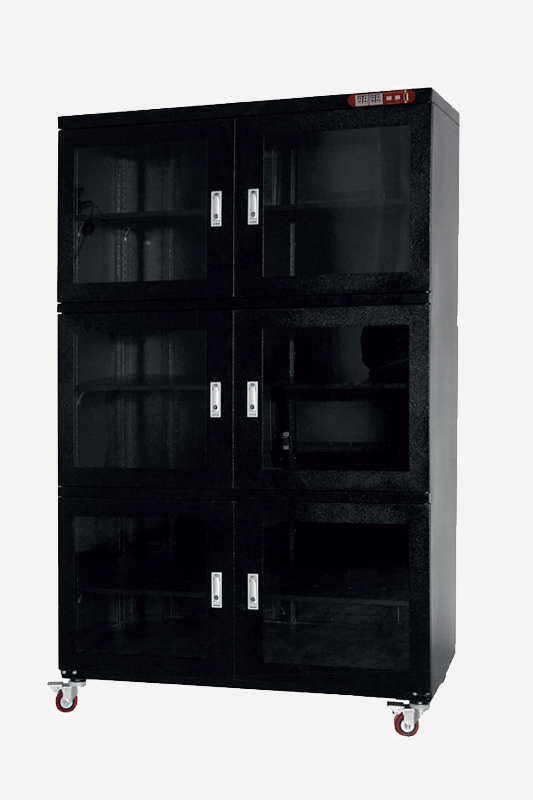

Electronics production and service are normally run in environments with 40-60% RH air humidity. This means that there is a need for a local reduction of air humidity in the storage spaces of components. Drying cabinets are commonly used for this purpose.

Devices of this type ensure and maintain the low degree of humidity necessary to ensure the safety of components in accordance with IPC standards. Based on the offer of REECO cabinets from the Polish company RENEX, we will look at the possibilities of this type of devices and factors that are worth paying attention to when making such an investment.

As with any other device introduced into a facility dealing with electronics the first thing to pay attention to when selecting a dry cabinet is whether it has been protected against electrostatic discharge. This is all the more important since there are devices on the market with a similar effect intended for storing, for example, chemicals, where such requirements do not exist.

All REECO products have been designed to operate within EPA zones by specialists in the field of electronics production.

The next step is to check whether the level of humidity maintained by the device complies with the standards provided for the storage of electronic components.

Again, the availability of devices from other industries, provided for other values may cause problems when choosing the right equipment. REECO devices ensure safe storage of components in accordance with the IPC / JEDEC J-STD-033B.1 standard, providing humidity of less than 5% RH, with the standard value being 2% RH.

What is particularly important, the drying modules in REECO products work all the time, maintaining the required level of air humidity regardless of the proper work of the sensors. This provides additional protection for stored components in the event of sensor failure.

A significant factor is also the ease of use of the devices. REECO drying cabinets are easy to use and do not require servicing from the panel. Installation is limited to connecting the device to a power source and does not require any settings.

The use of REECO drying cabinets is not limited to storing electronic components in them. They are top-class solutions what allows them to be used in all areas that require low humidity levels.

They ensure longevity of photographic and optical lenses, films, cameras, audiovisual devices, valuable papers and canvases, precision instruments as well as chemical and medical materials.

The housing of REECO drying cabinets has been manufactured from high quality 1 mm sheet metal protected by a hard resin coating and tempered glass of 3.2 mm thickness.

The door frames are covered with magnetic rubber to ensure a proper seal. The devices are not based on drying through heating, thanks to which they are energy-saving and there is no problem with condensation of water vapor and fan noise.

The average power consumption of the device is 47W, maximum 370W. REECO drying cabinets are available in 10 variants differing in capacity and the number of doors, which allows them to be adapted to any scale of activity.