RENEX Group has been distinguished among European companies with the title of the YAMAHA Golden Training Unit. The Polish company was appreciated for the technical knowledge and technological facilities it presents.

The certificates were awarded this year for the first time. YAMAHA’s goal was to distinguish a small group of European companies providing top quality training and consulting services in the field of automation and robotization of manufacturing processes.

RENEX Group was awarded the highest title – Gold Training Unit. The certificate was awarded for the high quality of its technical knowledge and technological facilities. RENEX Group operates within its RENEX TECHNOLOGY AND TRAINING CENTER a unit dedicated to robotics – the YAMAHA AUTHORIZED TRAINING CENTER.

The Center runs courses in the operation and programming of industrial robots. The aim of these activities is to provide a wide range of engineers with the knowledge and know-how to make the most of the capabilities of YAMAHA industrial robots and, consequently, to increase the profits of their users.

The Center’s infrastructure includes a wide range of YAMAHA industrial robots and robotic workstations created based on them – including many units of REECO Robot series – devices awarded with such distinctions as TERAZ POLSKA Emblem. As can be seen on their example, production line processes such as soldering, screw assembling, labelling, dispensing and other – depending on individual orders – can be easily robotised.

The topic of REECO Robots was recently raised by YAMAHA as a perfect example of the application possibilities of their equipment – https://fa.yamaha-motor-im.de/get-the-right-recipe-to-leave-the-others-behind/

The awarded certificate confirms the high level of the Center’s equipment in the scope of organisation of trainings. It was recognised that each participant may use a separate, fully functional robot station – including an industrial robot. The audio-visual equipment of the space, which allows for displaying materials on individual monitors, is also important for learning comfort.

RENEX Group organises online training courses also for foreign users. This form of training is popular with specialists not only from Poland, but also from Germany, Serbia, Bosnia and Herzegovina, Bulgaria, Croatia, Macedonia and Romania.

Due to the wide range of devices available on site and the highest level of training, YAMAHA specialists are also trained at the Center.

A big part of the success is YAMAHA’s technological achievements. In 2020 alone, YAMAHA introduced three state-of-the-art pieces of equipment: including a new SCARA robot model, a series of linear conveyors and a vision system.

SCARA YK-XE ROBOTS

Two new models in the SCARA YK-XE series have been introduced: the YK610XE-10 with an arm length of 610 mm and the YK710XE-10 with an arm length of 710 mm. The devices are based on the proven technology of the current YK-XE series with a maximum payload of 10kg and a standard cycle time of 0.39 seconds (YK610XE-10) or 0.42 seconds (YK710XE-10).

With the 400mm arm length SCARA YK400XE-4 robot introduced late last year, the YK-XE series now includes three models, giving an even wider range of applications – from handling and sorting small components in manufacturing such as smartphones and computers, to working with large components such as those used in household appliances and the automotive industry.

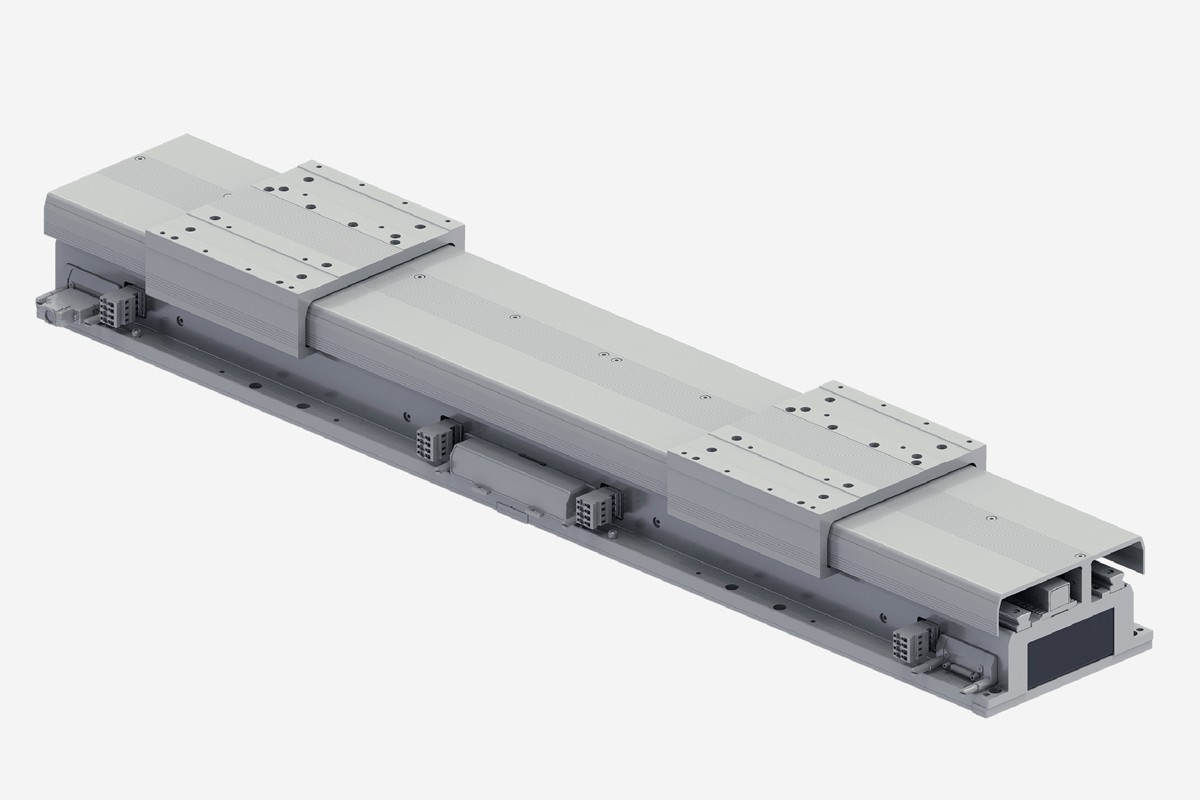

LCMR200 LINEAR CONVEYORS

YAMAHA recently also introduced linear conveyors in the new LCMR200 series. The designers have maintained the high accuracy and short stroke characteristic of the previous LCM-100 model, but have improved the module design. The linear guide and carriage rail have been enlarged and strengthened, while maintaining the same overall size. The result is a more robust model that is better suited for environments where foreign objects and static noise are present.

The system allows up to 64 sliders to be supported by a single YHX controller, and the creation of a new programming model using the Standard Profile eliminates the need to program individual controller events. This greatly simplifies the integration process.

RCXIVY2+ VISION SYSTEM

Another of YAMAHA’s new product launches is the new RCXiVY2+ vision system, which is capable of detecting irregularly shaped objects, making it suitable for applications in the food, pharmaceutical, cosmetics and apparel industries, among others.

The system is equipped with a new high-performance camera, and thanks to its enhanced processing capabilities, its recognition time is up to 45% faster than the current iVY2 model.

The new model is also fully integrated with robots by incorporating vision, lighting and tracking control cards into the RCX3 series robot controller. This change enables robot control, image processing, lighting control and conveyor control from the robot program, significantly reducing setup time.

If you are interested, please contact RENEX Group Technical and Sales Advisors – dth@renex.pl and visit www.renex.pl